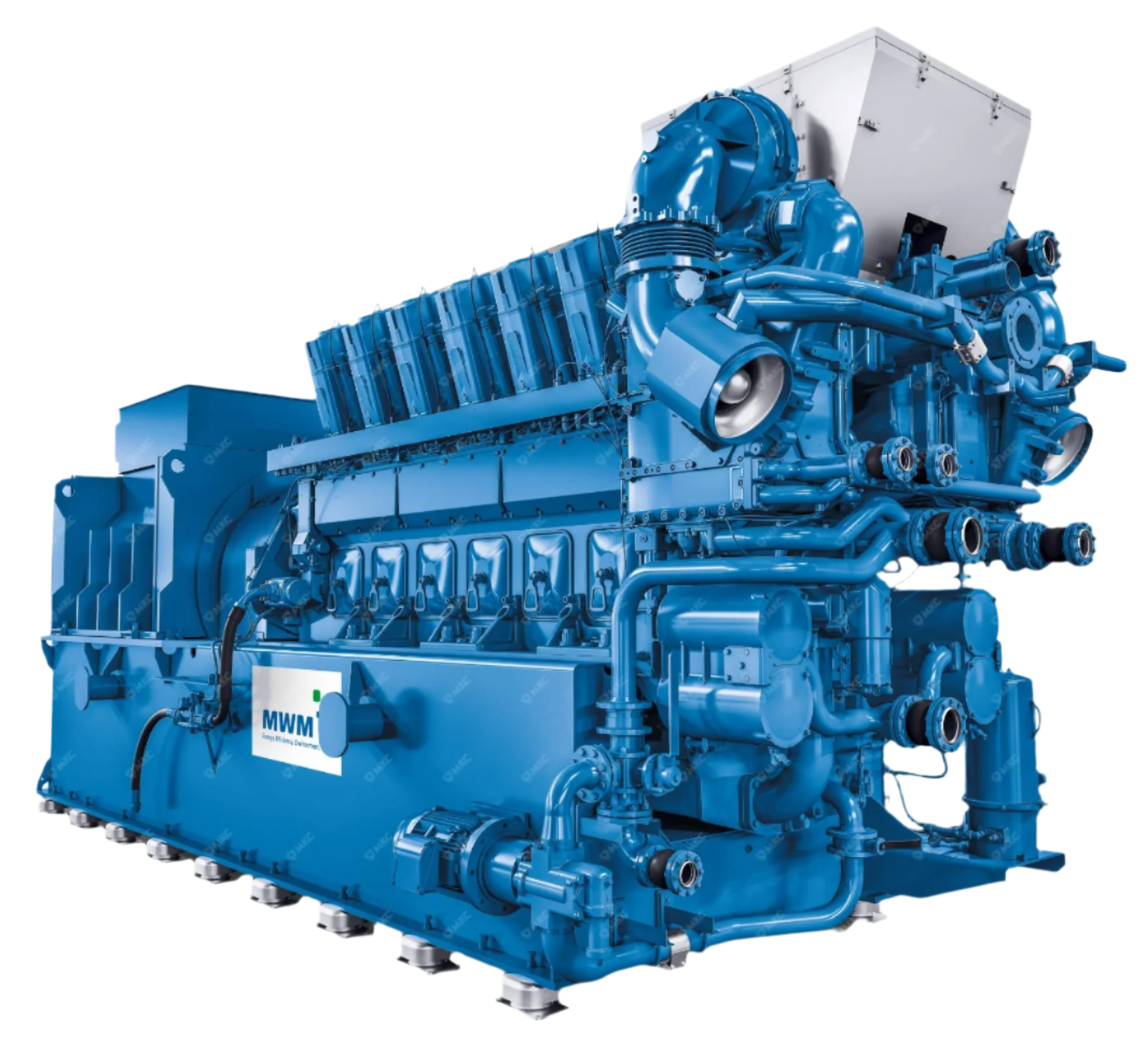

Contaminated diesel fuel is responsible for an estimated 65% of unplanned generator failures. Water ingress, particulate dirt, rust flakes, and microbial growth clog injectors, erode fuel-pump plungers, and cause incomplete combustion that coats turbochargers in soot. A robust fuel-filtration strategy—incorporating bulk-tank water separation, multi-stage on-engine filters, and routine maintenance—is critical for generator reliability. This article explores filter technologies, sizing guidelines, and field-proven practices for stationary diesel generator sets.

Sources of Fuel Contamination

- Condensation: Diesel contains dissolved water that condenses on tank walls during temperature swings, especially in humid climates.

- Tanker delivery: Poorly maintained trucks may introduce sludge, debris, or water from previous fills.

- Microbial growth: Bacteria and fungi thrive at the fuel–water interface, forming sludge and acids.

- Rust and scale: Moisture in steel tanks creates oxide particles that abrade fuel injectors.

- Dust ingress: Open or unfiltered vents draw airborne particles into storage tanks.

Filtration Performance Metrics

The Beta ratio (βx) is used to define filter efficiency. For example, β5 = 200 means the filter removes 99.5% of particles ≥ 5 µm. High-pressure common-rail systems require β4 ≥ 200 to protect injectors.

| Stage | Micron Rating | Typical β Ratio | Purpose |

|---|---|---|---|

| Bulk tank coalescer | 30 µm | β30 > 75 | Removes free water and coarse solids |

| Pre-filter / water separator | 10 µm | β10 ≥ 75 | Captures remaining water and large particulates |

| Secondary engine filter | 2 µm | β4 ≥ 200 | Protects injectors and high-pressure pump |

Water Separation Technologies

- Coalescing media: Multi-layer synthetic fibres combine small water droplets into larger ones that settle out by gravity.

- Centrifugal separators: Use spinning motion to force water to the outside while fuel remains at the centre.

- Water-absorbing polymers: Swell and block flow upon contact with water, acting as a backup safety measure.

For standby sets, a duplex coalescer with manual changeover allows filter service without shutting down the generator.

Filter Housing Selection and Sizing

- Design for pressure drop ≤ 25 kPa on suction side and ≤ 50 kPa on pressure side at rated flow.

- Use clear polycarbonate water bowls rated UL 94 V-2 for visibility, or metal bowls with sight glass for high-risk rooms (e.g., fire-pump applications).

- Install heater elements in the filter bowl for cold climates to prevent wax dropout below 5 °C.

- Include hand priming pumps to simplify bleeding after filter service.

Fuel Polishing Systems

For tanks storing diesel longer than 6 months, a recirculating polishing skid is recommended. Typical system features include:

- Gear pump (24 h rated) delivering 1–2 tank turnovers per day

- 30 µm bag filter → 10 µm coalescer → 2 µm absolute cartridge

- Water-in-fuel sensor with automatic drain solenoid

Jubaili Bros offers 500 l/h and 1 000 l/h skids with Deep Sea controller integration for run-time logging and remote alarm.

Maintenance Intervals and Indicators

| Component | Interval | Service Guidelines |

|---|---|---|

| Bulk tank coalescer | Annually or ΔP > 20 kPa | Replace filter; drain water weekly |

| Pre-filter / water separator | 250 h (standby) / 500 h (prime) | Replace filter; clean bowl |

| Secondary engine filter | 250 h (standby) / 500 h (prime) | Replace when ΔP gauge exceeds 45 kPa |

| Polishing skid filters | Every 1 000 h polishing | Replace based on weight or ΔP alarm |

Fuel Sampling and Quality Testing

Laboratory testing every quarter is recommended. Key parameters include:

- Water & sediment (% v/v)

- ISO 4406 cleanliness code

- Microbial count (CFU/mL)

- Density and sulphur content

- Flash point (°C)

Diesel should meet ≤ 0.05% water & sediment and ISO 18/16/13 or cleaner for common-rail engines.

Troubleshooting Quick Guide

- Black exhaust smoke under load: Check air filter and post-filter ΔP; may indicate high fuel flow or restricted airflow.

- High ΔP after filter change: Wrong element rating—replace with OEM 2 µm.

- Frequent water sensor alarms: Replace coalescer; inspect vent breather and tank gaskets.

- Engine hunting: Check for air ingress at filter head and hose fittings on suction side.

Best Practices in GCC Conditions

- Use desiccant breathers with check valves; replace when silica gel changes colour.

- Paint external tanks white or reflective to reduce heat gain and condensation.

- Rotate fuel stock annually; drain bottom low points every quarter.

- Dose with broad-spectrum biocide (150 ppm) after each fuel delivery.

Conclusion

Fuel cleanliness is essential for modern diesel engines. Tight injector tolerances leave no room for error. Multi-stage filtration, reliable water separation, and disciplined fuel management convert stored diesel into a dependable power reserve.

Need help designing or retrofitting a fuel-filtration system? Contact Jubaili Bros – we supply duplex coalescers, polishing skids, and lab test kits tailored to local GCC conditions.