Over the last decade, declining photovoltaic (PV) costs and advancements in lithium-ion battery storage have significantly reshaped off-grid and remote power system design. Applications such as mining camps, telecom towers, agricultural sites, and eco-resorts are increasingly shifting from full diesel reliance to hybrid micro-grids. These combine solar generation, energy storage, and diesel generators with intelligent controllers to deliver reliable, sustainable, and cost-effective power.

Jubaili Bros has implemented hybrid solutions across diverse sectors, achieving up to 70% fuel savings while improving uptime and reducing CO2 emissions. This article outlines the core architecture, sizing strategies, and integration best practices based on our technical experience across the Middle East and Africa.

Why Hybrid Systems Make Sense

- Fuel Cost Reduction: Every kilowatt-hour generated by PV displaces diesel, cutting operating costs by 30–70%. In sunny regions, fuel savings of over 400,000 litres annually are achievable in medium-scale deployments.

- Extended Generator Life: Reduced runtime delays major overhauls, lowers maintenance frequency, and mitigates wet-stacking from low loads.

- Lower Emissions: Each litre of diesel avoided reduces CO2 output by approximately 2.7 kg, supporting ESG targets and regulatory compliance.

- Better Power Quality: Batteries respond instantly to load fluctuations, stabilising voltage and frequency before the diesel generator can react.

Typical System Architecture

Modern hybrid micro-grids generally include:

- Solar PV array: Often rooftop or ground-mounted, feeding hybrid or grid-tied inverters.

- Battery Energy Storage System (BESS): Typically lithium-ion based, coupled with a bidirectional inverter and Battery Management System (BMS).

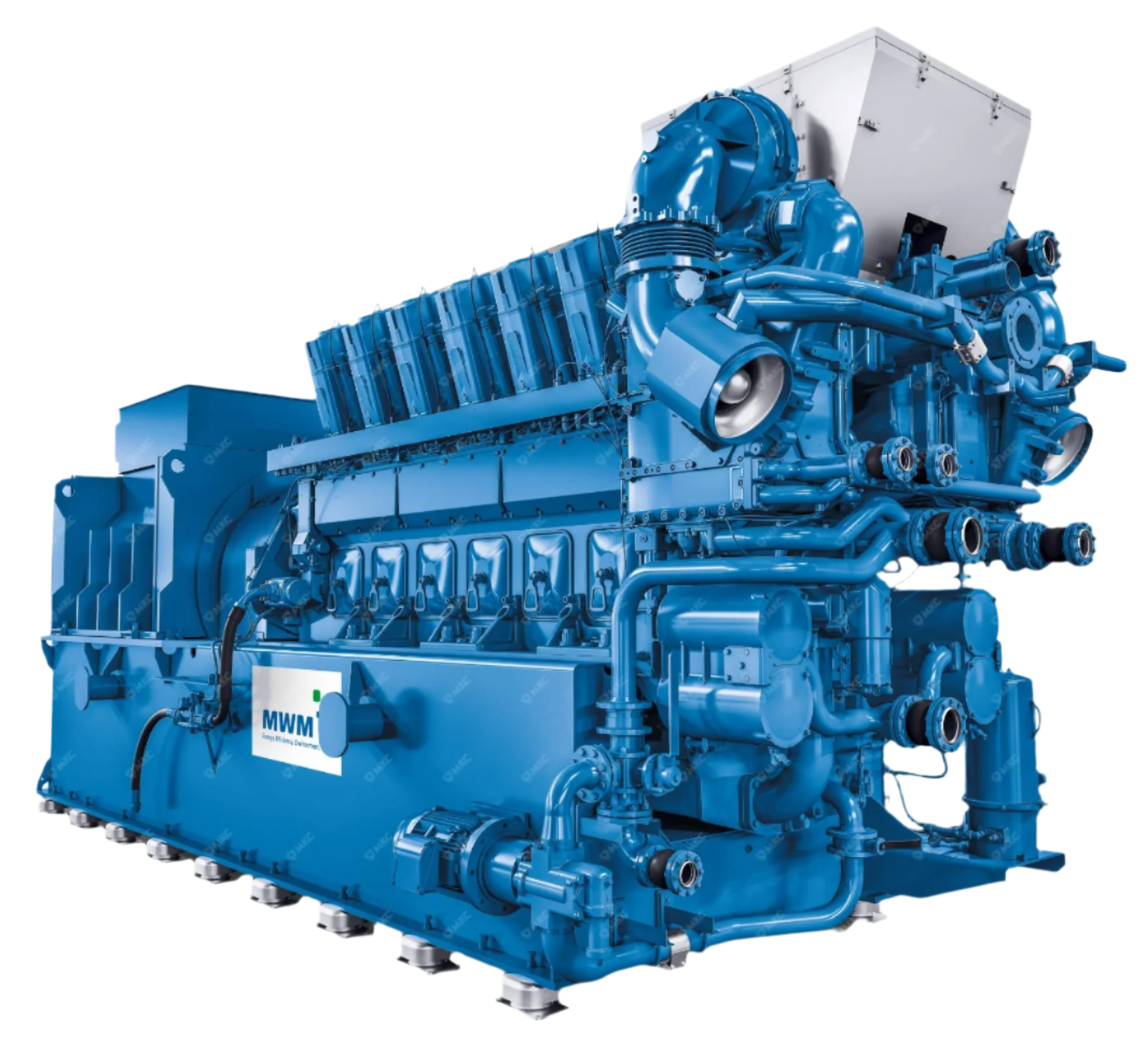

- Diesel generator: Sized for peak load or as spinning reserve.

- Hybrid Controller: Such as the DSE 8660 or 8710, managing load dispatch between PV, battery, and genset based on demand and State of Charge (SoC).

Jubaili Bros integrates Fronius, SMA, or Huawei inverters using Modbus or CAN protocols, ensuring compatibility with Deep Sea controller features like remote access, performance logging, and predictive maintenance alerts.

Operating Modes and Transitions

| Mode | PV | Battery | Generator | Use Case |

|---|---|---|---|---|

| PV Priority | Maximum | Charging | Off or low-load | Daytime peak irradiance |

| Battery Discharge | Low or none | Discharging | Off | Evening or low-load hours |

| Genset Support | Curtailed | Optional | Running at 30–60% load | Cloudy weather or high night loads |

| Diesel Only | Offline | Idle | Full load | Night or maintenance mode |

How to Size a Hybrid System

Load Profile: Collect hourly data over at least 7 days. For telecom, use flat 24/7 loads; for industrial or hospitality, use a variable demand curve.

Solar Potential: Adjust Global Horizontal Irradiance (GHI) for soiling, module mismatch, and temperature. Typical AC yield is 1,500–1,800 kWh/kWp/year in the MENA region.

Battery Capacity: Design for 4–6 hours of autonomy at average load. Factor 80% DoD and end-of-life degradation. C-rate typically C/4 to C/6.

Genset Derating: Use ISO or OEM derating factors for altitude and temperature. Include 10–15% headroom for future load growth or spinning reserve requirements.

Controller Strategy and Integration

The DSE 8660 enables ramp-down setpoints, load management, and inverter curtailment via Modbus. It supports both grid-forming and grid-following inverters and includes droop-based load sharing between generator and battery inverter. Recommended settings include:

- Governor droop: 4% (diesel)

- Inverter droop: 2%

- Minimum genset load: ≥30% to avoid wet-stacking

Worked Example – Mid-Scale Deployment

Average load: 300 kW Annual demand: 2,628 MWh PV installed capacity: 1,200 kWp → 1,800 MWh/year Battery shift capacity: 450 MWh/year Diesel requirement: ~828 MWh/year Diesel consumption: ~215,000 litres/year Diesel-only baseline: ~685,000 litres/year Annual fuel savings: ~470,000 litres (AED 1.4 million)

Design and Safety Considerations

- Anti-Islanding: Required in grid-tied applications. Compliant with IEEE 1547, G99, and other interconnection codes.

- Short-Circuit Current: Inverter fault current is typically 1.1 p.u., significantly lower than alternator fault currents (6–8 p.u.). LV gear must be rated accordingly.

- Grounding: Ensure only one N-E bond point. Floating PV or battery inverters must be properly referenced.

- Harmonics: Use inverters with active filtering or harmonic shaping if connected to sensitive loads like VSDs or telecom equipment.

Commissioning Checklist

- Update firmware on DSE controller to latest hybrid-compatible version.

- Verify PV inverter and battery inverter settings (voltage, droop, max/min SoC limits).

- Simulate a full daily load cycle and record generator start/stop timings, SoC curve, and PV curtailment events.

- Test under peak load with no PV to ensure genset alone meets critical demand.

Operation and Maintenance

Battery Management: Maintain 15–30 °C ambient for optimal cycle life. Integrate HVAC alarms and SoC calibration reminders into controller.

PV Cleaning: Dust accumulation in Gulf climates can reduce yield by 5–10%. Schedule cleaning at least monthly during dry seasons.

Generator Runtime Logs: DSE controllers log runtime, fuel used, and battery interactions—data vital for preventive maintenance and warranty tracking.

Common Integration Pitfalls

- Oversized PV with undersized BESS: Leads to frequent curtailment, reducing ROI.

- No spinning reserve: If PV fails suddenly, the genset must ramp instantly—keep it warm and partially loaded.

- Poor SoC calibration: Leads to premature generator starts and inefficient cycling. Calibrate coulomb counters quarterly.

Conclusion

Hybrid micro-grids built around diesel, solar, and battery systems offer proven cost savings, reduced environmental impact, and improved system resilience. Success depends on precise sizing, robust controller integration, and thoughtful load management. With the right expertise, these systems deliver high returns and payback periods under three years.

Considering a hybrid solution? Contact Jubaili Bros for feasibility studies, turnkey EPC execution, and long-term O&M support.