How to Select and Install an Automatic Transfer Switch

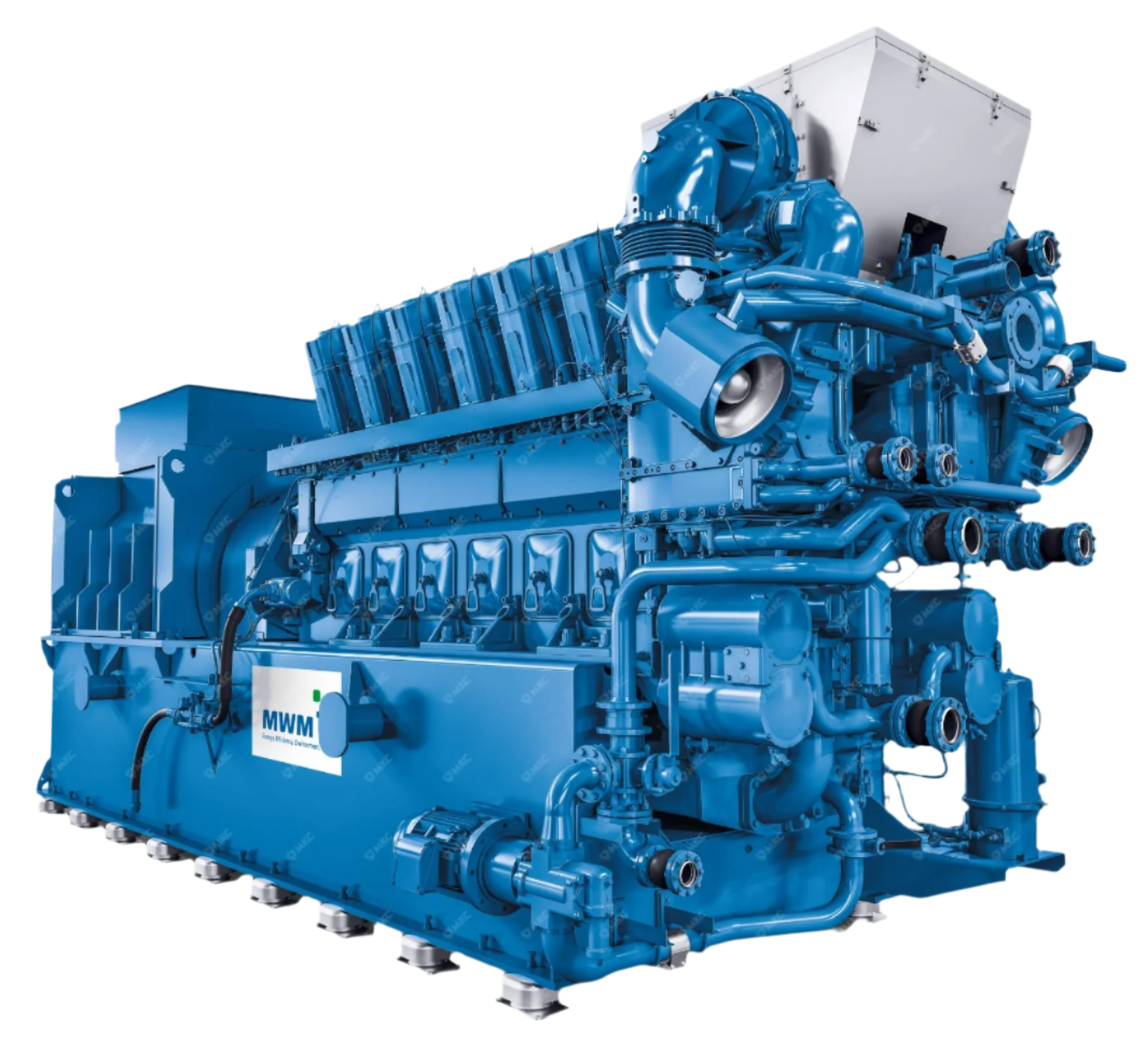

When the utility supply fails, an Automatic Transfer Switch (ATS) is the single most critical component that determines whether your facility switches smoothly to standby power—or sits in silence. To function reliably, the ATS must be properly sized for fault duty, configured with the correct transition logic, and integrated with the generator controller and protection systems. This guide summarizes Jubaili Bros’ experience across thousands of diesel and gas generator installations, offering practical advice on selecting, installing, and maintaining ATS equipment that ensures both uptime and safety.

Principle of Operation

An ATS continuously monitors the preferred source (typically utility power) and automatically transfers the load to an alternate source (such as a generator) when voltage or frequency fall outside acceptable thresholds. Once mains power stabilizes, the ATS switches back after a delay. Modern systems use microprocessor-based controllers like the DSE 7320 AMF module, which offer Ethernet connectivity, scheduling, and detailed event logs for maintenance and compliance.

Common ATS Architectures

- Contactor-based: Uses two mechanically interlocked or motorized contactors; ideal for compact systems up to ~1600 A.

- Breaker-based: Employs two molded-case or power circuit breakers for higher short-circuit performance and onboard protection—common above 1600 A or for closed-transition systems.

- Rotary transfer switch: A cam-driven design allowing near-seamless “make-before-break” transfer; suitable for applications requiring zero interruption.

- Static transfer switch (STS): Utilizes thyristors to enable sub-4 ms transfer for IT or mission-critical loads; more expensive and heat-intensive.

Transition Modes

Open transition (break-before-make): The generator starts upon mains failure. A short blackout occurs during transfer, acceptable in most industrial settings.

Closed transition (make-before-break): Both sources synchronize briefly (usually ≤100 ms) to avoid interruption. Requires synchronizing logic via controllers like the DSE 8610, which aligns voltage, frequency, and phase before breaker closure.

Delayed transition: Introduces a pause in the neutral position to allow motor loads to coast down before re-energization, avoiding damage from out-of-phase switching.

ATS Sizing Criteria

| Parameter | Recommendation |

|---|---|

| Continuous current (A) | Size for ≥125% of full-load current to allow for future growth. |

| Short-circuit withstand | Verify Isc at the installation point; breaker-based ATS is often needed for systems above 35 kA RMS symmetrical. |

| Withstand and close-on rating (WCR) | Should exceed the fault current from both generator and utility sources. |

| Motor inrush | Ensure the switch handles 6× FLA for 30 seconds unless soft starters are used. |

| Neutral pole | Use a 4-pole switched neutral if UPS systems, earth-fault monitoring, or multiple sources are connected to neutral. |

Control and Protection Integration

Controllers like the DSE 7320 provide outputs such as generator start, mains healthy, and generator available to drive ATS logic. For multi-generator systems, the DSE 8610 offers CANbus communication for load sharing, black-start sequencing, and grid synchronization.

Do you need droop CTs? Not for generator-to-generator synchronization—modern controllers manage this digitally. However, droop CTs are still required for utility-parallel applications to meet grid protection standards.

Installation Best Practices

- Cable routing: Separate utility and generator feeds to avoid back-feed risk. Label all connections clearly.

- Voltage sensing: Place sensing taps upstream of the ATS to ensure proper detection of utility failure.

- Grounding: Bond the ATS enclosure to the facility earth grid. Target resistance: <0.1 Ω.

- Environmental rating: In hot or dusty regions, use NEMA 3R or IP54 enclosures rated above 45 °C.

- Test capability: Include a manual test lever or controller function for monthly exercise without load interruption.

Maintenance Schedule

- Monthly: Exercise the transfer switch under load. Confirm timer and voltage sensing calibration.

- Semi-annually: Inspect for contact wear or pitting. Retorque terminal connections to spec.

- Annually: Perform insulation resistance testing, calibrate protection relays, and update firmware.

- Every 3 years: Conduct infrared thermography at full load to detect hot spots. Replace arc chutes if worn.

Conclusion

An ATS is more than just a switching device—it is the brain and muscle behind reliable standby power. Proper sizing ensures fault durability, and integration with advanced controllers like the DSE 7320 or 8610 enables fast, safe, and compliant transfers. With the right installation, routine testing, and proactive maintenance, your ATS will remain as dependable as the generator it commands.

Contact Jubaili Bros to speak with our engineering team about ATS selection, commissioning, or integration support.