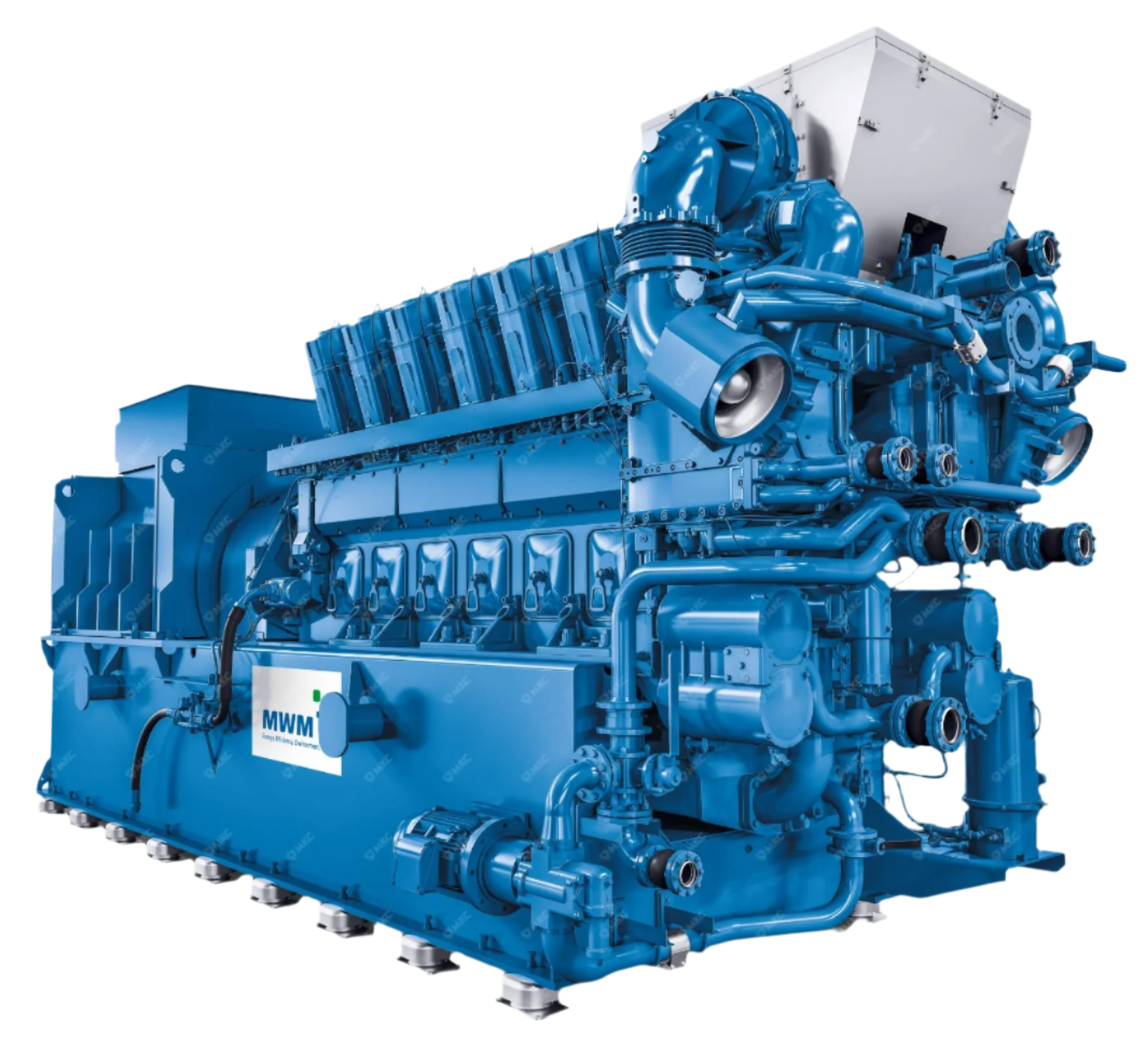

Roughly two-thirds of the chemical energy in diesel fuel is rejected as heat. Only about one-third is converted into useful mechanical energy to drive the alternator. The waste heat must be expelled through two primary paths: the exhaust system (≈ 40%) and the cooling system (≈ 30%). If the jacket-water circuit, charge-air cooler, or radiator cannot dissipate this thermal load, engine metal temperatures rise, lubricating oil breaks down, and catastrophic failure can occur. A generator’s cooling system is therefore not a secondary accessory—it is critical to long-term reliability. This article compares the main cooling options—set-mounted radiators, heat exchangers, and remote radiators—along with selection criteria and maintenance best practices.

Cooling System Fundamentals

Diesel engines use pressurised coolant circulated through engine passages by a mechanically driven water pump. Heat is then removed by either a radiator or a heat exchanger. Fans—either mechanical or electric—generate airflow across the cooling surface. Generator enclosures must also ventilate heat from alternator losses and exhaust manifold radiation. While ventilation design is discussed in Article 12, this article focuses on the liquid cooling circuit.

Set-Mounted Radiators

Most generator sets up to 1 500 kVA include a core-mounted radiator with a belt- or hub-driven fan. This “draw-through” configuration pulls air from the alternator end, across the engine, and out through the radiator matrix. Advantages include:

- Factory-matched sizing and minimal installation complexity.

- No external pumps or field piping required.

- Compact footprint and lowest total cost of ownership.

However, performance may suffer in rooms with poor airflow or high acoustic restrictions. Airflow resistance exceeding ~120 Pa (≈ 12 mm H2O) can reduce fan output and elevate coolant temperatures beyond the 95 °C design limit.

Tropical vs Temperate Radiator Packs

Radiators are rated based on ambient air-on temperature. Temperate packs are typically rated for 40 °C, while tropical packs handle 50 °C or higher. For example, a 1 000 kVA engine shedding 300 kW via coolant requires ~8 m³/s airflow at 40 °C. At 50 °C, cooling demand increases by approximately 25%, requiring larger cores or higher fin density. Jubaili Bros specifies tropical cores as standard across Gulf installations.

Heat Exchangers (Keel-Cooling)

In marine or industrial sites with an external chilled water loop, a tube-and-shell heat exchanger replaces the radiator. Coolant circulates through internal tubes, while external water absorbs the heat via conduction.

Benefits:

- Virtually silent operation inside the generator room.

- No reliance on ventilation for engine cooling.

- Compact engine layout with no fan or radiator housing.

Challenges include managing water chemistry, fouling control, and installation of secondary circulation pumps and strainers.

Remote Radiators

In applications where airflow restrictions, acoustic baffles, or room geometry preclude effective ventilation, the radiator is relocated outdoors. The fan is powered by an electric motor, usually controlled by a variable frequency drive (VFD). Jubaili Bros recommends remote radiators when total static pressure exceeds 125 Pa or when internal room temperature rise exceeds 6 °C.

Piping and Pumping Design

Remote systems add elevation and friction head to the cooling circuit. Flow rate must be verified using manufacturer-supplied pump curves. Maintain coolant velocity ≤ 2 m/s to prevent erosion, and use EPDM hoses rated for 110 °C continuous service. Rigid pipes must be anchored to prevent movement, and flexible bellows should isolate vibration from the engine.

Controls and Safety

Effective control of remote radiators requires:

- Thermostatic bypass valves to prevent over-cooling during light load.

- Fan VFDs linked to coolant outlet temperature for energy savings and noise control.

- High-temperature and low-level alarms connected to the generator controller.

Ambient Derating and Altitude

High ambient temperatures reduce heat transfer margin, while high altitudes reduce air density. Radiator capacity typically drops by 3% per 300 m elevation above sea level. At sites above 900 m, derate both engine and radiator or select a larger cooling frame accordingly.

Cooling System Maintenance

| Interval | Task | Notes |

|---|---|---|

| Weekly | Check coolant level and specific gravity | Target 50% glycol mix for freeze and corrosion protection |

| Monthly | Inspect fan belts for cracks or glazing | Replace as needed |

| Quarterly | Clean radiator fins using compressed air or water | Reverse-flush preferred in dusty environments |

| Semi-annual | Test coolant for pH and nitrite concentration | Maintain pH 8–10; top up inhibitors as needed |

| Every 2 years | Drain and replace coolant | Flush with deionised water to prevent scale |

Troubleshooting Over-Temperature Issues

- Fan not activating: Inspect fan motor, contactor, or VFD for faults.

- Blocked radiator: Check for visible blockage using a flashlight; clean if >30% surface is obscured.

- Cavitating pump: Listen for rumble or whining; inspect and replace impeller.

- Air-lock: Bleed air from high points after servicing the coolant system.

- Incorrect coolant mix: Pure water boils at 100 °C; glycol raises the boiling point and improves performance.

Integration with Generator Enclosures

In containerised sets, core-mounted radiators typically draw air through inlet louvres and exhaust it through the radiator. Maintain a free louvre area ≥ 3× radiator face area to ensure air velocity remains under 3 m/s. Use acoustic splitters with mineral wool lining to reduce fan noise by ~10 dB(A), adding minimal static resistance (<2 dB).

Emerging Technologies: Smart Cooling Controls

Modern generator controllers such as the Deep Sea 7320 MKII accept CAN-based temperature probes and modulate dual-speed electric fans based on load and coolant temperature. This reduces idle-time energy use by up to 60%. Advanced remote radiator modules now include predictive maintenance tools to monitor rising static pressure—a key sign of fin fouling or obstruction.

Conclusion

Whether using a factory-supplied radiator, a compact marine heat exchanger, or a remote rooftop radiator, cooling system performance is critical to generator reliability. Proper selection, sizing, and preventative maintenance prevent costly thermal shutdowns and extend engine life.

Need engineering advice on radiator sizing or remote loop design? Contact Jubaili Bros—our technical team can model airflow, pump duty, and derating factors to match your site conditions and operational profile.