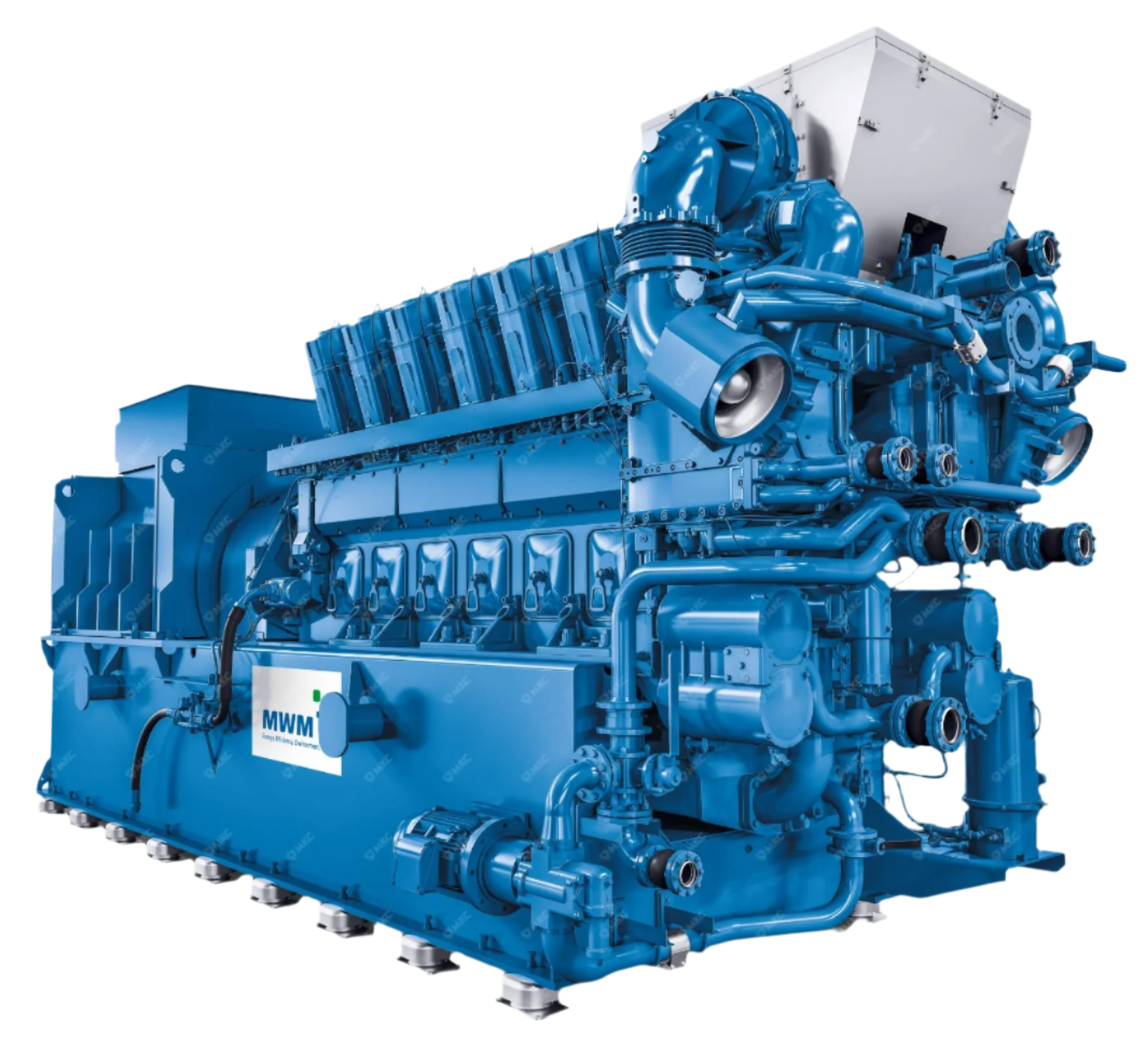

Diesel generators concentrate all three elements of the fire triangle in a confined space: fuel, oxygen, and heat. A rupture in a high-pressure fuel line or a turbocharger oil leak onto hot exhaust lagging can ignite within seconds, posing a serious threat to personnel safety and operational continuity. For this reason, modern building codes mandate dedicated fire-protection systems—including detection, alarm, containment, and suppression—tailored to generator-specific risks. This article distills key requirements from NFPA, FM Global, and Gulf-region civil defence codes.

Regulatory Framework

- NFPA 37: Installation and Use of Stationary Combustion Engines.

- NFPA 20: Fire Pumps (where the generator supplies a fire-pump driver).

- NFPA 110: Emergency and Standby Power Systems (Level 1 sets).

- UAE Fire & Life Safety Code / Saudi SBC 801: Local GCC implementation standards.

Typical mandates include 2-hour fire-rated enclosures, thermal-activated fuel shutoff valves at 100 °C, and clean-agent suppression systems for indoor generator rooms.

Fire Hazards in Generator Rooms

- Fuel spray: Diesel under 500 kPa can atomise through pinhole leaks and flash on contact with turbo housings.

- Oil mist: Vapour from crankcase breathers or oil leaks ignites near exhaust manifolds at ~200 °C.

- Electrical arcs: Battery cables and busbars can arc at temperatures exceeding 5 000 °C.

- Hot surfaces: Turbo-exit exhaust pipes can reach 500 °C; insulation failure exposes these ignition sources.

Detection Technologies

| Detector Type | Response Time | Advantages | Limitations |

|---|---|---|---|

| Rate-of-rise heat | 15–30 s | Insensitive to dust or mist | Slower on fast-flame events |

| UV/IR flame | < 5 ms | Immediate flame detection | Requires clear line of sight; higher cost |

| Linear heat cable | < 10 s | Wraps around manifolds; pinpoint accuracy | Vulnerable to abrasion or ambient heat |

| VESDA (aspirating smoke) | 10–30 s (pre-alarm) | High sensitivity; early warning | Requires clean airflow and regular maintenance |

Best practice: Use UV/IR flame detectors aimed at the engine skid, paired with rate-of-rise heat detectors at ceiling level. Both should be linked to the fire alarm control panel (FACP) with two-stage logic to prevent false discharges.

Suppression Agent Options

- FM-200 (HFC-227ea): Clean agent; no residue; 7–8% concentration; high global warming potential (GWP).

- Novec™ 1230: Fluoroketone; 5.6% concentration; low GWP; premium cost.

- CO2 flooding: Effective; displaces oxygen to <7%; hazardous to personnel—requires interlock and pre-discharge alarm.

- Water-mist: Fine spray <200 µm; cools hot surfaces; electrically safe; requires DI water and stainless steel piping.

- Foam-water spray: Used outdoors; suppresses fuel spills around open-frame sets.

In the GCC, clean agent or water-mist is typically approved for indoor generator rooms with occasional human access.

Fuel System Integration

Install a thermal fuel shutoff valve (fusible link at 70–100 °C) at the day-tank outlet. Connect the valve’s end-switch to the generator controller so that, in the event of valve closure, the generator logs a fuel-supply-failure and initiates a safe shutdown.

Generator Room Construction

- Fire-rated walls: 150 mm hollow block with intumescent coating or precast concrete for 2-hour protection.

- Fire door (180-minute rating): Self-closing, with panic hardware and magnetic hold-open tied to the FACP.

- Fire-rated penetrations: Intumescent collars on pipe and cable entries to maintain compartment integrity.

Ventilation Interlock

Upon suppression discharge, close room dampers and shut off supply and exhaust fans to retain the agent for a minimum 10-minute hold time. The fire panel should signal fan VFDs to stop via interlock.

Commissioning Checklist

- Pressure test suppression piping at 1.4× design pressure.

- Align and test flame detector field of view using a certified test lamp.

- Perform a door-fan test to confirm room leakage area ≤ 0.5 m² (for FM-200).

- Trigger simulated spill alarm; verify fuel-shut valve actuation and generator shutdown.

- Document agent discharge design: mass, concentration, nozzle layout, and hold time.

Maintenance Schedule

| Interval | Component | Task |

|---|---|---|

| Monthly | Agent cylinder | Check pressure gauge ≥ 95% design |

| Quarterly | Flame and heat detectors | Clean lenses and perform functional tests |

| Semi-annual | Fuel-shut valve | Cycle manually; inspect fusible link |

| Annually | Room integrity | Repeat door-fan test after structural changes |

| Every 5 years | Agent cylinders | Hydrostatic test; refill if weight < 95% |

Theoretical Case Study

In a 1 000 kVA generator room, a pinhole fuel leak at 350 kPa atomised onto a 450 °C turbocharger. A UV/IR detector identified the flame in 4 ms, prompting the fire panel to discharge 490 kg of FM-200 at 8% concentration. The fire was extinguished within 5 seconds. The fuel-shut valve closed and the generator coasted down. Post-event inspection revealed light soot but no structural damage. The system returned to service the same day after cylinder replacement.

Conclusion

Fast flame detection, automatic fuel isolation, and reliable suppression form the foundation of safe and code-compliant generator rooms. Fire protection is not a secondary feature—it is essential to long-term power reliability and safety assurance.

Need a turnkey fire-suppression package for your generator installation? Contact Jubaili Bros – our engineers provide CFD discharge modelling, UL/FM-rated equipment, and full civil defence submission support.