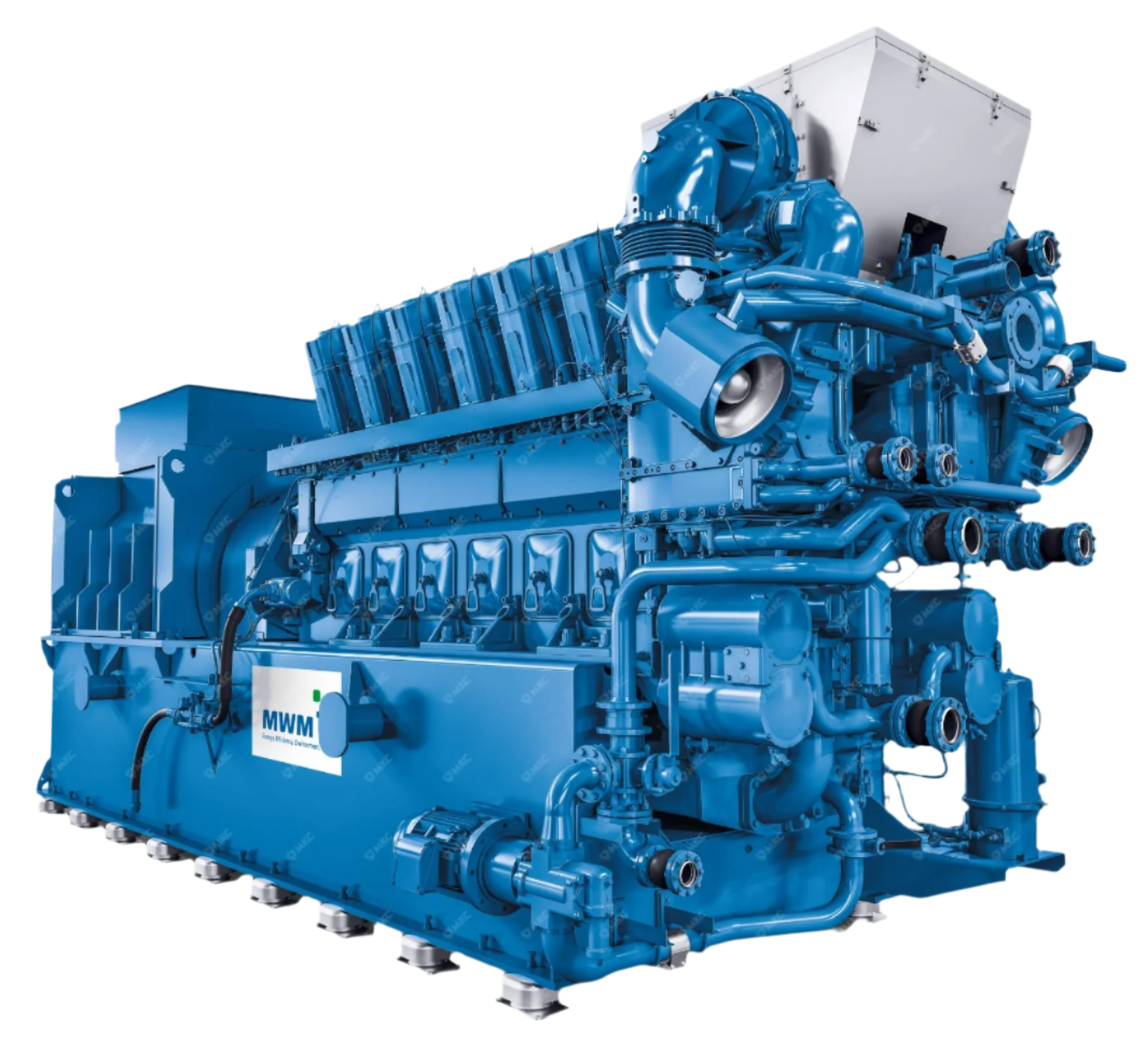

Proper exhaust system design is critical for diesel generator reliability, operator safety, and acoustic comfort. While the engine’s cooling system carries away roughly one-third of the fuel’s heat, another third leaves the set as hot exhaust gas. If that energy is not channelled and attenuated correctly, it can overheat the generator room, damage nearby structures, or exceed local noise regulations. This article explains the fundamentals of sizing, routing, supporting, and silencing exhaust systems for stationary generator sets in the 10 kVA–2 MVA range.

Why Exhaust Design Matters

Every litre of diesel fuel releases about 42 MJ of chemical energy. In a typical engine, approximately 33% is rejected through the exhaust. Unmanaged, this stream of hot gases can:

- Raise the ambient temperature in the generator room, reducing alternator life and derating power output.

- Create back-pressure that impairs engine breathing, affecting load response and fuel economy.

- Transmit low-frequency noise above 115 dB(A) at the stack outlet, exceeding OSHA and municipal limits.

- Introduce carbon monoxide (CO) and nitrogen oxides (NOx) into occupied zones.

Effective exhaust design addresses three performance areas: back-pressure, acoustic attenuation, and thermal/structural safety.

Calculating Acceptable Back-Pressure

Each engine has a maximum allowable exhaust restriction listed on its data sheet—typically 7–10 kPa at rated load. Oversizing the pipe reduces back-pressure and noise but increases cost and radiated heat. For optimal sizing:

- Obtain engine exhaust data: mass flow (kg/s) or volume flow (m³/min) and max permissible back-pressure.

- Select pipe diameter: Aim for gas velocity between 20–35 m/s. Lower velocities reduce noise but require larger pipe.

- Calculate friction losses: Use Darcy–Weisbach or equivalent pressure loss charts for the selected pipe size and layout.

- Include silencer loss: Add the pressure drop (∆P) from the selected silencer at design flow.

- Maintain margin: Ensure the total ∆P remains below 90% of the engine’s limit to accommodate fouling.

Example: A Perkins 2806C-E18TAG3 (650 kVA) produces 9.2 m³/s at 120 °C. A 200 mm Schedule 40 pipe (~0.192 m ID) gives ≈32 m/s. A 12 m run with two 90° elbows (K = 1.5 each) results in ≈3.4 kPa friction loss. Adding a hospital-grade silencer with 2.0 kPa ∆P yields a total of 5.4 kPa—safely within the 7 kPa allowance.

Routing and Support

Exhaust piping expands approximately 1 mm per metre per 100 °C. A pipe heated from 25 °C to 450 °C will expand about 4 mm per metre. To accommodate this:

- Use flexible bellows or braided stainless compensators between the turbo outlet and rigid piping.

- Install supports that allow axial movement—e.g., spring hangers or sliding shoes.

- Maintain a minimum 3° downward slope away from the engine to drain condensation.

- Ensure at least 1.5 × pipe diameter clearance from combustibles.

For roof penetrations, specify double-wall insulated breechings with weather flashing to meet fire codes and prevent water ingress.

Silencer Selection

| Type | Typical Attenuation (dB(A)) | ∆P (kPa) | Recommended Use |

|---|---|---|---|

| Reactive | 15–20 | 0.5–1.5 | Rural locations, non-critical equipment |

| Absorptive (straight-through) | 20–25 | 1.0–2.0 | Pump stations, industrial zones |

| Hospital (reactive + absorptive) | 25–35 | 1.5–3.0 | Hospitals, data centres, urban rooftops |

Note: Always compare octave-band attenuation data against the site’s noise limit. A silencer rated “25 dB(A)” may be insufficient at low frequencies unless additional lagging is applied.

Thermal Management and Insulation

Exhaust gases typically reach 450–550 °C. Lagging the first 6 m with 50 mm ceramic fibre can reduce surface temperature to under 80 °C—preventing burns and reducing room heat gain by up to 1.2 kW per metre. Insulation also cuts low-frequency noise by 2–3 dB(A).

As an alternative, pre-insulated double-wall stainless steel piping offers faster installation and a cleaner finish, though at higher cost.

Condensation and Wet-Stacking

Diesel sets operating below 30% load often produce unburned fuel vapour that condenses into acidic liquid—this process, called wet-stacking, damages silencers and deposits tar-like residue. Preventive steps include:

- Exercising at ≥ 50% load regularly, either through operational demand or load-bank testing.

- Installing drain taps at the lowest points of horizontal runs.

- Using stainless steel silencers (304/316) for standby generators in humid or corrosive environments.

Compliance with Emission After-Treatment

Where particulate or NOx reduction is required, the exhaust system must accommodate diesel particulate filters (DPF), selective catalytic reduction (SCR), or oxidation catalysts. These components add up to 10 kPa of back-pressure and require flanged joints for service access and sensor ports for temperature and NOx monitoring.

Commissioning Checklist

- Ensure all joints are gasketed and torqued; perform a soap-bubble leak test on startup.

- Measure static back-pressure at full load and record in the commissioning report.

- Verify stack exit velocity ≥ 35 m/s to prevent soot fallout and backflow into air intakes.

- Confirm that room temperature rise is below 7 °C; modify ventilation if exceeded.

- Take octave-band noise readings at 1 m from stack and at the site boundary.

Maintenance Guidelines

Exhaust systems often go unchecked after startup. Establish the following maintenance plan:

- Monthly: Inspect flex connectors for cracks or fatigue; open and drain any low-point taps.

- Quarterly: Retorque flange bolts; check for soot leakage indicating seal failure.

- Annually: Open silencer access panels to inspect baffles and corrosion. Replace any insulation that is oil-saturated or deteriorated.

- Every 3 years: Ultrasonic test carbon steel pipe for wall thinning in humid or coastal environments.

Conclusion

A properly designed exhaust system extends generator life, reduces operating costs, and ensures compliance with safety and environmental codes. Managing noise, heat, and back-pressure with care leads to quiet, efficient, and safe generator performance.

Have questions about sizing silencers, choosing materials, or integrating emissions control? Contact Jubaili Bros — our application engineers are ready to help.