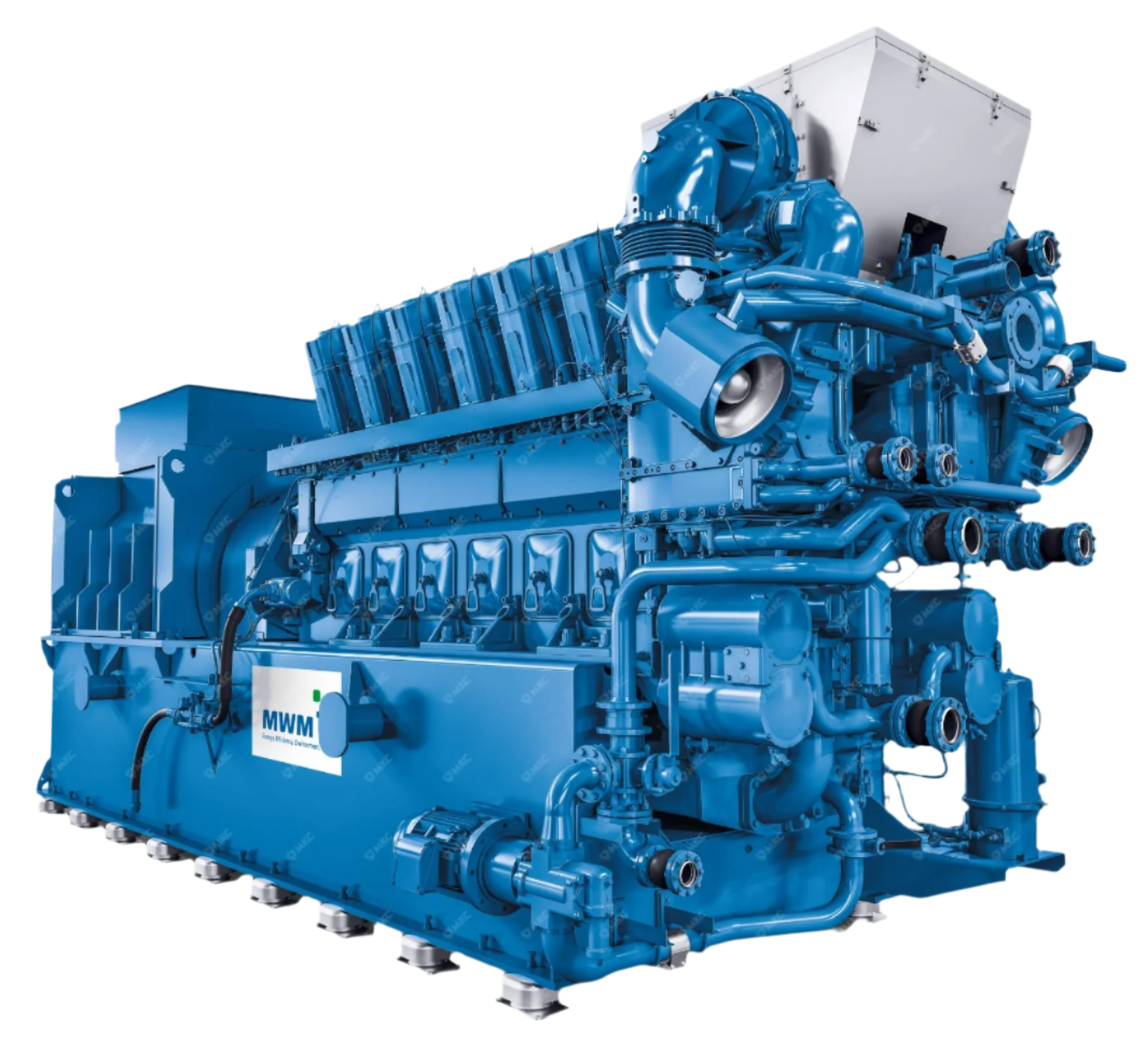

Diesel Generator Maintenance Schedule and Best Practices

A diesel generator is only as reliable as its maintenance plan. Skipping scheduled services is the fastest way to turn a backup power source into a liability. But how often you service a generator depends on its duty cycle, environment, fuel quality, and most importantly—run-hours. This article explains the key variables, offers a practical service schedule, and shows how Jubaili Bros supports generator owners through built-in controller alerts and direct OEM service programs.

Why Generator Maintenance Matters

Every startup imposes thermal and mechanical stress on the engine, alternator, and controls. Over time, oil degrades, filters clog, terminal connections loosen, and fuel systems become contaminated. Without routine checks, minor issues escalate into costly failures or long-term damage. Modern controllers like the Deep Sea DSE 7320 include a Maintenance Scheduler that tracks usage by calendar days or run-hours, ensuring tasks aren’t missed.

What Influences Your Maintenance Frequency?

- Usage Mode: Prime-power units accumulate hours quickly and need shorter service intervals. Standby units may run only a few hours per month.

- Environment: Dust, heat, humidity, and corrosive air (e.g., near the sea) increase wear on filters and coolant systems.

- Load Profile: Light loading below 30% of rated kW can cause wet-stacking and oil dilution, requiring closer monitoring.

- Fuel Quality: Water or sulfur contamination shortens fuel filter life and damages injectors.

- Regulatory Compliance: Healthcare and data centers often require monthly inspections and annual full-system servicing.

Recommended Service Intervals

The table below offers general guidelines for Perkins-powered sets up to 2 MVA. Refer to the engine OEM manual for exact intervals.

| Interval | Tasks | Notes |

|---|---|---|

| Before each run / Weekly | Check fluids, belt tension, battery voltage, alarm log | Log hours run |

| 250 hours or 6 months | Change oil and oil filter, clean air filter, drain fuel pre-filter, check governor and AVR | Shorter interval for dusty or hot environments |

| 500–600 hours or Annually | Replace fuel and coolant filters, inspect radiator, check head bolt torque, test batteries | Aligns with most warranty plans |

| 1 000–1 200 hours | Adjust valves, replace air filter, flush coolant, scan alternator, test protection relays | Schedule during planned downtime |

| 2 000 hours | Overhaul injectors, inspect turbo, verify fuel pump timing, check exhaust flex | May include emissions testing |

| 6 000–8 000 hours | Major overhaul: liners, pistons, bearings, crankshaft (based on oil analysis) | Budget and schedule ahead |

Prime vs. Standby Maintenance: A Comparison

A 500 kVA generator running 12 hours daily as a prime unit reaches 250 hours in just 21 days. In contrast, a standby generator used for monthly 30-minute tests logs only 6 hours annually. Regardless of usage, service is due when the first threshold—hours or time—is reached.

Using the Controller’s Scheduler Feature

Modern controllers such as the DSE 8610 and ComAp InteliGen series track run-hours and can schedule alerts based on custom thresholds. Multi-generator systems can automatically rotate load to balance engine wear. Jubaili Bros configures these alerts during commissioning so that operators receive reminders via display, SMS, or email.

Consequences of Missed Maintenance

- Lower Reliability: Clogged filters cause low pressure; dirty coolant leads to thermal shutdowns.

- Increased Costs: Skipping basic servicing leads to early injector or alternator failure—far costlier than routine filters.

- Warranty Issues: OEMs require proof of timely servicing. Jubaili Bros’ direct warranty model ensures coverage, but only with documented maintenance logs.

Best Practice Maintenance Tips

- Use genuine parts: Only original Perkins or Leroy-Somer components guarantee expected performance and life.

- Keep spares on site: Stock at least two sets of filters and fluids to avoid downtime during unplanned repairs.

- Trend performance data: Oil analysis and coolant testing can detect issues before they trigger alarms.

- Train your team: A simple daily walk-around by trained staff can prevent surprise failures.

Conclusion

There’s no universal service schedule, but a 250–500–1 000-hour framework supported by weekly checks and controller alerts works for most diesel generators up to 2 MVA. Pair this with Jubaili Bros’ technical support, OEM parts, and maintenance scheduling tools for long-term reliability.

Contact Jubaili Bros to request a site-specific service plan or consult our team about optimising your generator maintenance program.