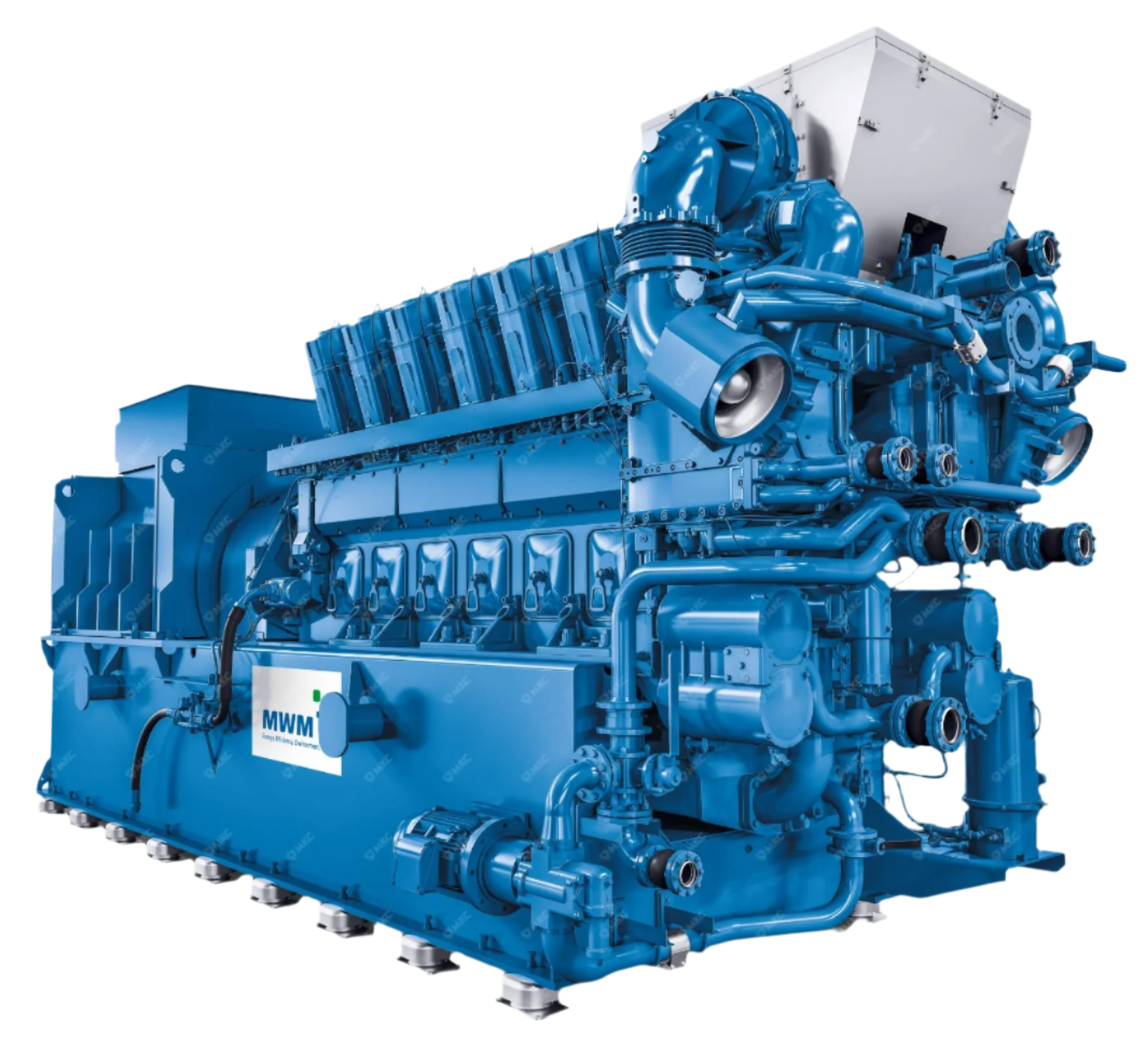

Diesel Generator Lubrication Strategy for Longer Engine Life

Engine oil acts as a coolant, hydraulic medium, detergent, and corrosion inhibitor. But generators—especially those running under low load or sitting idle—face unique lubrication challenges: fuel dilution during cold starts, moisture ingress from humid conditions, and soot buildup from low-temperature combustion. A disciplined lubrication strategy that includes proper oil selection, sampling, analysis, and timely changes can significantly extend engine life and reduce costly overhauls.

Functions of Engine Oil

- Hydrodynamic lubrication: Maintains oil film between crank journals and bearings.

- Boundary lubrication: Reduces wear at cam lobes and injector plungers under high pressure.

- Cooling: Up to 40% of heat from pistons is removed via oil jets.

- Detergent/dispersant action: Prevents soot aggregation and sludge formation.

- Neutralisation: Buffers acidic combustion residues via Total Base Number (TBN).

Oil Classification and Selection

| Standard | Typical Grade | Sulfated Ash (%) | TBN (mg KOH/g) | Application |

|---|---|---|---|---|

| API CK‑4 | 15W‑40 | ≤ 1.0 | 8–10 | Tier 3 / Stage III engines |

| API FA‑4 | 10W‑30 | ≤ 1.0 | 8–10 | Fuel-efficient road engines; limited genset use |

| ACEA E9 | 15W‑40 | ≤ 1.0 | 9 | Tier 4 Final with DPF/SCR |

| ACEA E2 (legacy) | 20W‑50 | ≤ 1.5 | 12 | Older pre-emissions engines |

Engines with DPF or SCR require low-ash oils (≤ 1%) to prevent clogging. When using high-sulphur diesel (> 0.5%), a high TBN (≥ 12) oil is needed to neutralize acidic by-products.

Oil Change Intervals

Baseline oil change intervals are 250 hours for standby generators and 500 hours for prime-power sets. These may shorten based on operating conditions such as:

- Fuel with high sulphur content (> 500 ppm)

- Low load operation (< 30% rated kW)

- High dust environments contributing to silicon wear

- Use of emergency bypass filtration

With consistent oil analysis, intervals may extend to 1 000 hours or more. Key indicators include viscosity, TBN, soot, and wear metals.

Sampling and Analysis Protocol

- Warm engine to ≥ 80 °C before drawing a 100 ml mid-stream sample.

- Label samples with unit ID, run hours, oil hours, top-up volumes, and fuel sulphur rating.

- Test for viscosity (40 °C), TBN, insolubles, PQ index, and wear metals (Fe, Cu, Al, Si, Pb).

- Track data in your CMMS system; flag alerts if iron > 100 ppm or TBN < 4.

Interpreting Wear-Metal Trends

- Iron and chrome: Indicates cylinder or ring wear—check air filtration system.

- Copper and lead: Bearing fatigue or cavitation symptoms.

- High silicon (> 20 ppm): Airborne dirt—inspect pre-cleaners and filter seals.

- Soot > 3%: Low-load operation—consider load bank testing or injector inspection.

Filtration Systems

Full-flow filters remove particles > 25 µm, while bypass filters remove finer debris (1–5 µm). Use only OEM-certified filters with correct bypass valve ratings to ensure proper cold-start operation.

Coolant and Fuel Interactions

- Glycol contamination: Triggers potassium and sodium spikes—check liner O-rings and head gaskets.

- Fuel dilution: Seen as reduced viscosity and flashpoint—revisit cold-start settings or prolonged idling behavior.

Best-Practice Maintenance Schedule

| Interval | Task | Target |

|---|---|---|

| Every 250 h (standby) | Change oil and filter | API CK‑4 15W‑40 |

| Every 500 h (prime) | Change oil and filters | — |

| Every 250 h | Oil sampling | Viscosity ±12%; TBN > 4 |

| Annually | Inspect breather and PCV system | No sludge or backpressure |

Storage and Handling

- Store sealed drums in cool, dry locations below 25 °C. Use FIFO rotation.

- Deploy color-coded transfer pumps to prevent cross-contamination.

- Install Beta 3 > 200 inline drum filters when refilling tanks.

Conclusion

Oil is the diesel engine’s most critical fluid. Selecting the correct type, maintaining clean delivery, and acting on analysis results transforms oil management into preventive maintenance that safeguards against expensive engine failure and downtime.

Need lab kits or on-site oil analysis training? Contact Jubaili Bros – we supply ISO-certified oil sampling tools and provide expert interpretation to extend the life of your generator.