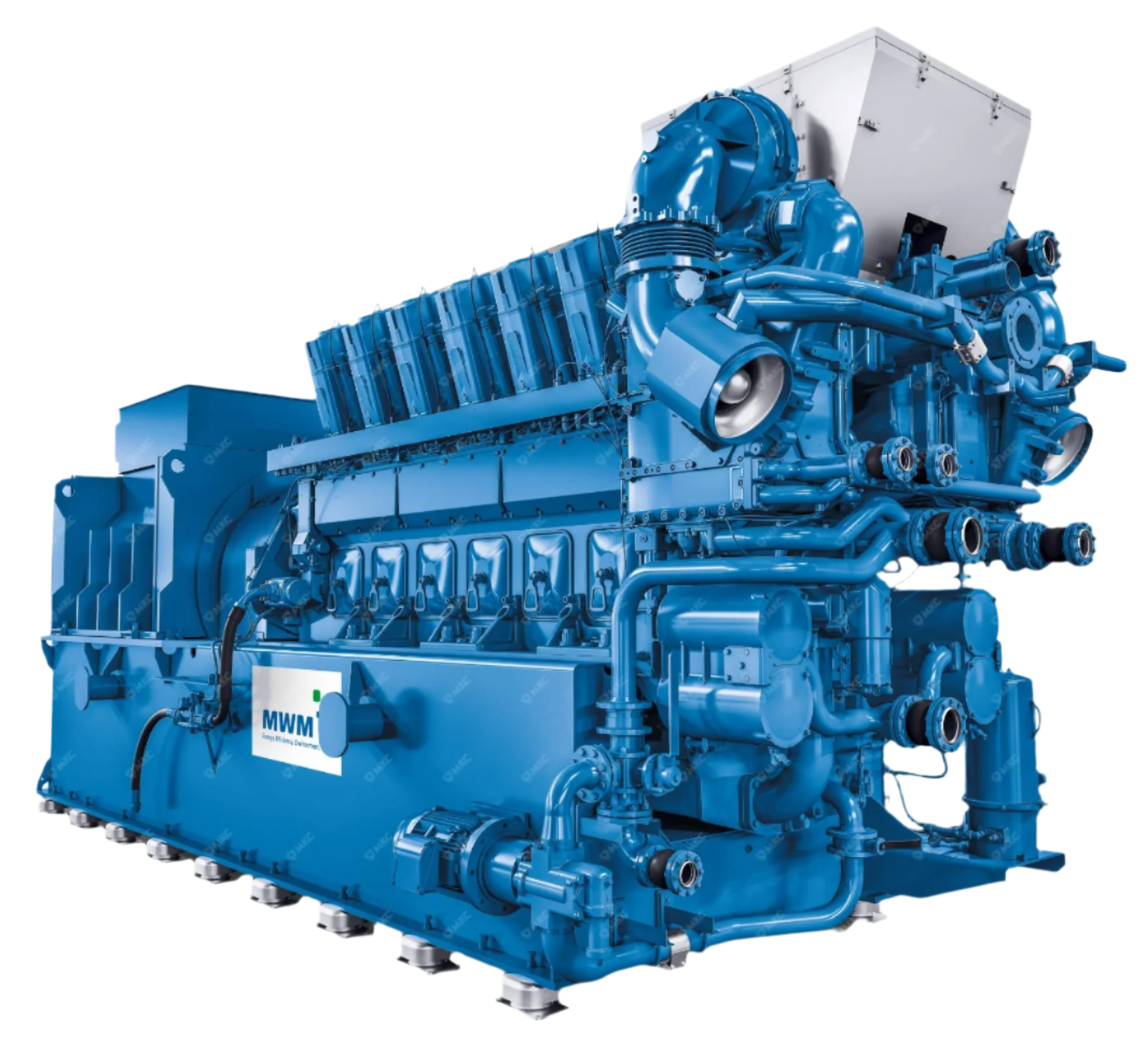

In the world of diesel generator operation, a curious paradox exists: The smallest portion of your total operational budget—preventive maintenance—has the most profound impact on your generator's reliability, performance, and lifespan. Yet despite this outsized importance, maintenance is frequently the first aspect to be compromised when budgets tighten or operational demands increase.

The True Cost Equation of Generator Operation

When evaluating the total cost of operating a diesel generator, most owners focus on the visible expenses: initial purchase price, fuel consumption, and major repairs. Preventive maintenance often appears as a relatively minor line item in comparison, typically representing less than 10% of lifetime operational costs. This modest financial footprint can create a dangerous illusion that maintenance is somehow less essential.

In reality, this small investment in preventive care has a multiplier effect on all other aspects of generator operation. Regular, quality maintenance dramatically extends equipment life, improves fuel efficiency, prevents catastrophic failures, and ultimately delivers the lowest total cost of ownership over the generator's lifetime.

The Hidden Consequences of Deferred Maintenance

The decision to postpone or minimize preventive maintenance is often driven by immediate concerns: cost reduction pressures, lack of qualified personnel, or simply the absence of visible problems. However, these short-term savings invariably lead to significantly higher long-term costs through multiple pathways:

- Accelerated Component Wear: Small issues that could be addressed during routine maintenance grow into major system failures requiring expensive repairs.

- Decreased Fuel Efficiency: Even minor deviations from optimal operation can increase fuel consumption by 5-10%, silently draining operational budgets.

- Extended Downtime: Reactive repairs typically take 3-5 times longer than planned maintenance, resulting in extended operational disruptions.

- Shortened Equipment Life: Properly maintained generators can operate effectively for 15-20 years or more; neglected units often require replacement in less than half that time.

- Emergency Repair Premiums: Unplanned repairs typically cost 50-200% more than the same work performed during scheduled maintenance.

The mathematics are clear: For every dollar "saved" by deferring maintenance, most operators end up spending $3-$10 in premature repairs, increased fuel costs, and shortened equipment life.

The Quality Factor: Not All Maintenance Is Created Equal

Even organizations that recognize the importance of regular maintenance may compromise on another critical factor: the quality of parts and expertise applied during service. Using substandard components or inadequately trained technicians introduces risks nearly as significant as skipping maintenance entirely.

Generic or counterfeit parts might appear identical to original components, but often lack the precise specifications, material quality, and testing rigors of genuine Marapco parts. These differences may be invisible initially but become painfully apparent through premature failures, incompatibility issues, and collateral damage to connected systems.

The Jubaili Bros Solution: Expertise Meets Excellence

Jubaili Bros addresses both the consistency and quality aspects of generator maintenance through our comprehensive approach:

- Customized Maintenance Contracts: Our service agreements are tailored to your specific operational requirements, ensuring appropriate maintenance frequency without unnecessary costs.

- Factory-Trained Technicians: Our service personnel receive the same rigorous training as our manufacturing teams, ensuring complete understanding of system interdependencies.

- Genuine Marapco Parts: We exclusively use original components that match the exact specifications of your generator, ensuring perfect compatibility and maximum longevity.

- Comprehensive Documentation: Each maintenance visit produces detailed records that build a complete operational history, enabling predictive maintenance approaches.

Through this integrated approach to preventive maintenance, Jubaili Bros helps customers achieve the lowest possible total cost of ownership while maximizing system reliability—proving that sometimes, the smallest investment truly does deliver the greatest return.