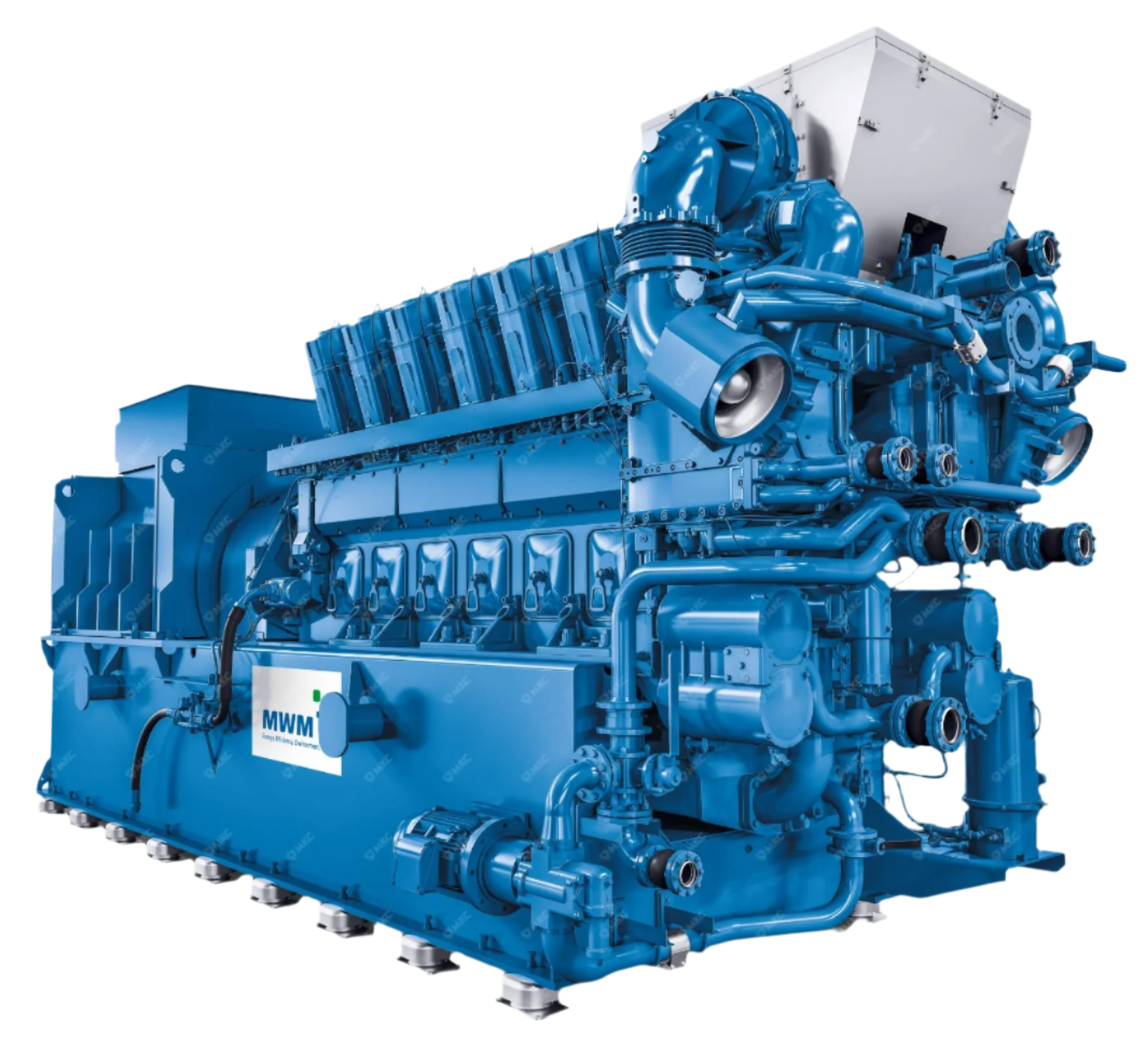

Adding a second generator set provides N + 1 redundancy, modular power expansion, and the ability to service one unit while maintaining uninterrupted operation. However, multiple sets only outperform a single unit if they share kW and kVAr reliably and disconnect without causing damaging voltage transients. This article explores the principles of synchronising, load sharing, and protective relaying to help consultants and facility managers design resilient multi-set generator systems.

Why Parallel Generator Sets?

Compared with a single large genset, a paralleling configuration offers:

- Redundancy: One unit can undergo maintenance without compromising critical loads.

- Efficiency: Operating multiple sets at 60–80% load is more efficient than running a single oversized unit at 30%.

- Modularity: Capacity can grow with demand by adding generators to the common bus.

- Lower fault contribution: Smaller alternators reduce short-circuit current, simplifying switchgear specification.

Synchronisation Fundamentals

To safely connect two live sources via a circuit breaker, four synchronisation parameters must align:

- Voltage matching: Within ±5% of bus voltage.

- Frequency matching: Within ±0.2 Hz to minimise beat effects.

- Phase angle: Ideally within ±10°, never exceeding ±15°.

- Phase sequence: Must be identical across all sets (e.g., ABC or UVW).

A synchroscope or microprocessor-based controller continuously monitors these values and closes the breaker when all conditions are satisfied.

Load Sharing Principles

Once synchronised, generators must divide load proportionally. Active power (kW) is regulated by the engine’s fuel input, while reactive power (kVAr) is controlled through excitation. Jubaili Bros training captures this as: “Supplying more fuel keeps speed constant but increases kW; supplying more excitation keeps voltage constant but increases kVAr.”

Digital controllers like the DSE 8610 exchange kW and kVAr data via CANbus every 50–100 ms, adjusting fuel and excitation to maintain error margins within 2%.

| Parameter | Typical Load Sharing Accuracy* |

|---|---|

| Active power (kW) | ±2.0% of rated generator power |

| Reactive power (kVAr) | ±5.0% of rated kVA |

*Assumes ISO 8528 Class G3 alternators and CANbus line length under 200 m.

Droop vs Isochronous Modes

Traditional governors relied on speed droop, where frequency decreases slightly under load, allowing stable sharing without communication. Modern systems support Isochronous kW & kVAr sharing, designating one set as master with others following, eliminating frequency drift and improving precision.

Are droop CTs still needed? Not for generator-to-generator synchronisation. Digital controllers integrate droop simulation, eliminating the need for external CTs. However, a droop CT is still required when synchronising with the utility to meet grid protection requirements.

Controller Architecture

- DSE 8610: Supports up to 32 sets with dead-bus logic, hours-run balancing, ROCOF/vector-shift protection, and Ethernet connectivity.

- DSE 8620 / 8660: Adds full mains-parallel control, including peak shaving and export limits.

- Governor and AVR: Use CAN/J1939 protocols for real-time speed and voltage control, including power factor set-points.

Protection Scheme Essentials

- Reverse power (ANSI 32): Trips the breaker if a generator becomes a motor.

- Under/Over frequency (81) and voltage (27/59): Protect against instability or loss of source.

- Rate of change of frequency (ROCOF 81R): Detects islanding in grid-parallel operation.

- Vector shift (78): Identifies sudden phase angle jumps caused by grid disturbances.

Design Best Practices

- Busbar rating: Size for total current of all gensets plus 25% spare capacity.

- CAN wiring: Maintain 150 mm separation from power cables; terminate with 120 Ω at both ends.

- Phase rotation check: Confirm correct phase sequence before first synchronisation to avoid mechanical damage.

- Harmonic suppression: Use 2/3-pitch alternators to reduce triplen harmonics—critical for UPS-heavy installations.

- Future expansion: CAN-based MSC systems allow new sets to be added live; reserve IP addresses and breaker space accordingly.

Commissioning Checklist

- Update all controller firmware to matching versions.

- Calibrate CT and VT ratios; confirm correct power readings at various power factors.

- Run a black-start scenario—verify master selection and slave synchronisation.

- Apply a 0–100% load step; check for frequency recovery under 3 seconds and voltage dip under 15%.

- Simulate a governor or AVR fault and confirm only the affected generator trips while the bus remains stable.

Maintenance Schedule

| Interval | Task |

|---|---|

| Monthly | Run synchronising test; inspect CANbus and Ethernet ports for corrosion or wear. |

| Quarterly | Download controller logs; verify hours-run balancing is active. |

| Annually | Test all protection relays via primary injection; clean and inspect controllers; apply firmware updates. |

Conclusion

Paralleling generators unlocks redundancy and scalability—but only if synchronisation, load sharing, and protection systems work in harmony. With digital controllers like the DSE 8610, modern AVRs, and a carefully commissioned installation, facility owners can achieve seamless power transitions and optimise fuel use across multiple units.

Need support designing or commissioning a multi-set generator system? Contact Jubaili Bros—our engineers specialise in synchronised and scalable power solutions.