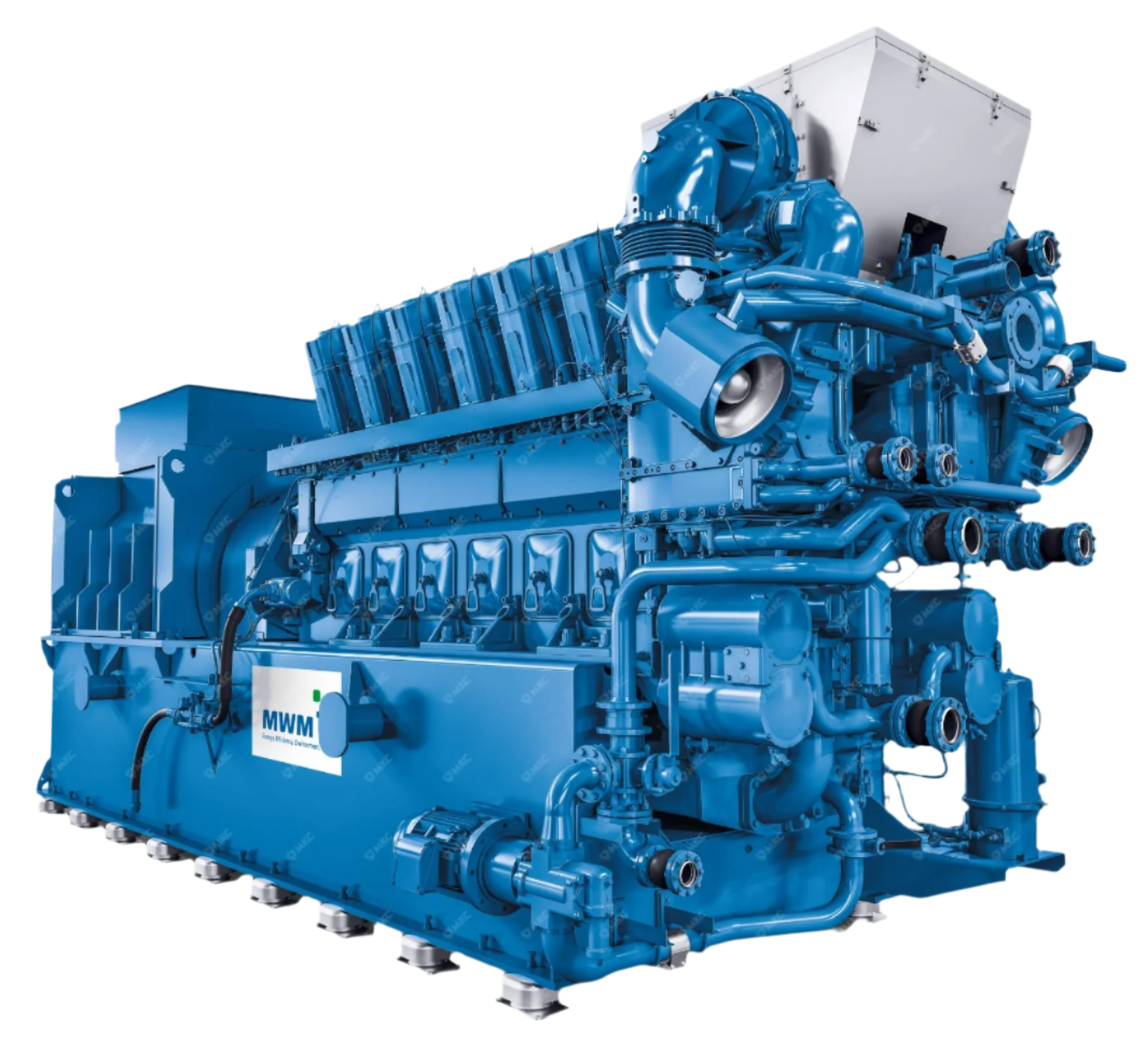

As environmental regulations tighten and sustainability goals grow more urgent, biodiesel has emerged as a viable alternative to traditional fossil diesel in power generation. But is it suitable for your generator? The answer depends on several factors—engine compatibility, fuel quality, maintenance practices, and storage conditions. This article explores the pros and cons of biodiesel use in diesel generators, especially those supplied by Jubaili Bros, and explains how to apply it safely and effectively in line with manufacturer recommendations.

Understanding Biodiesel and Its Blends

Biodiesel is a renewable, biodegradable fuel made from vegetable oils, animal fats, or recycled cooking grease. It is chemically known as fatty acid methyl ester (FAME) and is typically blended with petroleum diesel in ratios such as B5 (5% biodiesel), B20 (20% biodiesel), or B100 (100% biodiesel).

The most common blend used in standby and prime power diesel generators is B5 to B20. These low to medium biodiesel concentrations offer a balance between emission reduction and operational reliability. However, moving beyond B20 introduces more complexity, including the need for fuel system modifications and stricter maintenance procedures.

Generator Compatibility with Biodiesel

Many Perkins engines supplied by Jubaili Bros are certified to operate on biodiesel blends up to B20, provided that the fuel meets stringent international specifications, such as ASTM D6751 or EN 14214. These standards regulate key properties like viscosity, water content, sulfur level, and oxidative stability.

Engines compatible with B20 typically include:

- Perkins 1100, 2200, and 2500 series with electronic fuel injection

- 4000 series units used in prime and standby applications

- Engines with common-rail injection and programmable ECMs

It is important to note that B100 is not approved for use in standard generator sets unless explicitly stated by the engine manufacturer and accompanied by system upgrades such as FKM (Viton) seals, preheaters, and specialized filtration systems.

Key Benefits of Using Biodiesel

When used correctly and within approved limits, biodiesel offers multiple advantages:

- Reduced emissions – Biodiesel can lower CO₂ emissions by up to 80% compared to petroleum diesel, as well as cut down on unburned hydrocarbons and particulate matter.

- Improved lubrication – Biodiesel has superior lubricity, which can extend fuel system life, particularly in low-sulfur diesel environments.

- Domestic supply – Biodiesel is often locally sourced, reducing dependence on imported fuels and improving energy security.

In a video published by Jubaili Bros and Perkins, these benefits are discussed in more detail, highlighting biodiesel's role in enabling cleaner and more sustainable energy solutions in developing markets.

Challenges and Risks of Biodiesel Use

Biodiesel is not without its operational drawbacks, especially at higher blend ratios or in sensitive environments:

- Filter clogging – Biodiesel acts as a solvent and can loosen deposits in fuel tanks, which then clog filters during the initial transition period.

- Water absorption – Biodiesel is hygroscopic, meaning it attracts and absorbs moisture, which can promote microbial growth and lead to fuel system corrosion.

- Cold flow issues – Biodiesel has higher cloud and pour points than regular diesel, making it more prone to gelling in cold weather unless treated with additives.

- Shorter shelf life – Oxidative stability of biodiesel is lower, requiring turnover within 6 months unless properly stabilized.

To mitigate these risks, Jubaili Bros recommends that clients use high-quality biodiesel from accredited suppliers and follow best practices in storage and handling.

Storage and Fuel System Considerations

When switching to biodiesel blends, fuel infrastructure must be reviewed for compatibility:

- Replace natural rubber seals and gaskets with FKM or PTFE materials.

- Ensure tanks are clean and free of sludge before first fill.

- Install water separators and fuel polishing systems if storing for extended periods.

- Monitor fuel temperature and install heaters if ambient conditions drop below 10°C.

Jubaili Bros can assist in inspecting fuel systems and advising on required upgrades during the commissioning of biodiesel-capable sets.

Maintenance Implications

Maintenance intervals may require adjustment when using biodiesel. Jubaili Bros recommends the following:

- Fuel filter replacement – Double the frequency during the first 50–100 hours after switching to biodiesel, then monitor pressure drop.

- Injector inspection – Biodiesel can degrade under heat, leaving carbon residues; periodic pop-testing is advised.

- Oil analysis – Biodiesel tends to increase dilution risk. Perform periodic oil sampling to check for viscosity changes and acid number rise.

Engine control modules (ECMs) on Perkins units can be reprogrammed to adjust injection timing slightly for biodiesel, further enhancing combustion stability.

Warranty and OEM Guidelines

Jubaili Bros maintains warranty coverage for Perkins-powered generator sets using biodiesel up to B20, provided the fuel quality meets the standards mentioned above and storage conditions are controlled. However, failures due to poor fuel quality or microbial contamination are excluded from coverage.

Customers are encouraged to retain fuel purchase documentation and service logs, as warranty teams may request these during claims assessment.

When to Use Biodiesel

Biodiesel is ideal for:

- Government or NGO projects with renewable energy mandates

- Data centers seeking carbon footprint reduction

- Facilities with access to consistent, high-quality B5–B20 supply

- Remote sites with in-house fuel management systems

For customers in the UAE, Saudi Arabia, or Nigeria—where ambient temperatures are high and supply chains variable—Jubaili Bros offers project-specific guidance to ensure biodiesel integration is safe, compliant, and cost-effective.

Summary Checklist for Consultants

- Confirm generator set compatibility with B5–B20 blends.

- Source biodiesel from certified suppliers (ASTM D6751 or EN 14214).

- Clean fuel tanks before biodiesel transition.

- Use water separators and test for microbial contamination periodically.

- Monitor and replace filters more frequently.

- Log maintenance and fuel deliveries to maintain warranty eligibility.

Conclusion

Biodiesel offers a path to lower emissions and enhanced sustainability, but it must be implemented with care. At Jubaili Bros, we support our clients through the entire fuel transition process—from technical assessment to post-installation service. Whether you're retrofitting an existing genset or specifying new equipment, we ensure compatibility and performance every step of the way.

Have questions about biodiesel compatibility or fuel system upgrades? Contact Jubaili Bros—our engineers are ready to help design a fuel strategy that meets your operational and environmental goals.